Common Types of Plastic Pallets

Dec. 9, 2022

The various plastic pallets on the market, do you know how to distinguish between them?

Firstly, according to the surface structure of the pallet, it is divided into flat pallets and grid pallets.

Secondly, according to the bottom structure of the pallet, it is divided into single-sided nine-legged, three-runner, six-runner pallets, and double-sided pallets.

And finally, according to the weight of plastic pallets, it can be divided into light pallets medium pallets and heavy pallets.

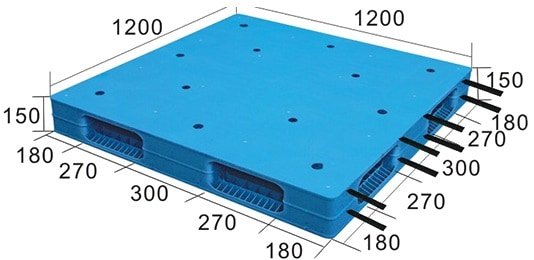

Flat pallets, which flat surfaces, smooth and easy to clean.

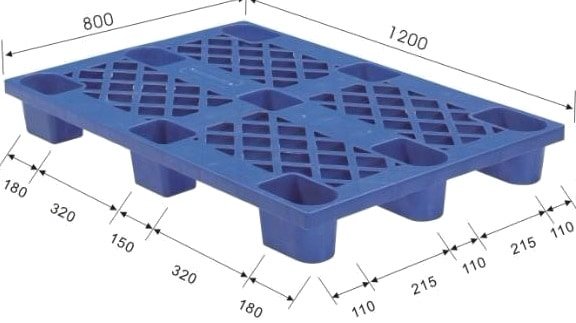

Grid pallets, the surface is fine grid, good ventilation.

In the daily handling turnover and storage of goods, grid pallets are easy to deposit dust and product powder in the surface and voids, not easy to clean. But in the same pallet size, grid pallets use less material than flat pallets, and the price is more advantageous.

The nine-legged plastic pallet is forked on all sides, which can be used with manual forklifts and mechanical forklifts, which are simple and convenient to operate.

Flat nine-legged plastic pallets are widely used in textile factories, food factories, pharmaceutical factories and other enterprises.

Grid nine-legged plastic pallets are not suitable for the use of shelves or heavier goods, most of them are used as warehouse goods cushion board anti-slip and also used for the turnover of lighter goods. The nine-legged pallet is a great advantage as empty pallets can nest within each other to take up as little room as possible.

Three runner pallets, the bottom design of this style is convenient for a variety of forklifts, and steel pipes can be built into the pallet, which is suitable for various shelves in the warehouse. Compared with the grid three-runner pallet, the flat three-runner pallet has a larger bearing capacity and stronger impact resistance. It is used in various industries such as electronic manufacturing, paper industry, chemical industry, logistics industry, warehouse shelf, food, machinery, etc. The grid three runner shaped pallet has good ventilation, lightweight, and relatively inexpensive price.

Six-runner plastic pallets are mostly used by mechanical forklifts in factory warehouses because manual forklifts are not convenient enter the jack of the pallet and can only be used for mechanical forklifts. Compared with grid field-shaped plastic pallets, flat field-shaped plastic pallets have better stability when carrying goods. In the container, handling and transportation of goods, import and export trade, automobiles, food, tobacco, medicine, paper industry, hotels, printing, electronic appliances, chemical industry, clothing, textile, warehousing, and logistics in grid field shape plastic pallets have a wide range of applications.

Double-sided plastic pallets can be used both front and back, making them suitable for racking and stacking. It is often used in food and beverage, flour deep processing, chemical plants, cold storage, and other industries.

The light, medium, and heavy weights of plastic pallets are divided by the weight of the pallet itself. If it is light, it is for 6-10 kg, mainly in the shape of nine legs; The medium size is 10-20 kg, mainly in the six-runner Pallet and Three Runner type, while the heavy type is more than 20 kg, and the double-sided type is dominant.

So see here do you know how to choose the style of the pallet?

I believe your answer is YES!

Powerjet large two-platen injection molding machines can meet the plastic pallets injection production requirements of different size standards!