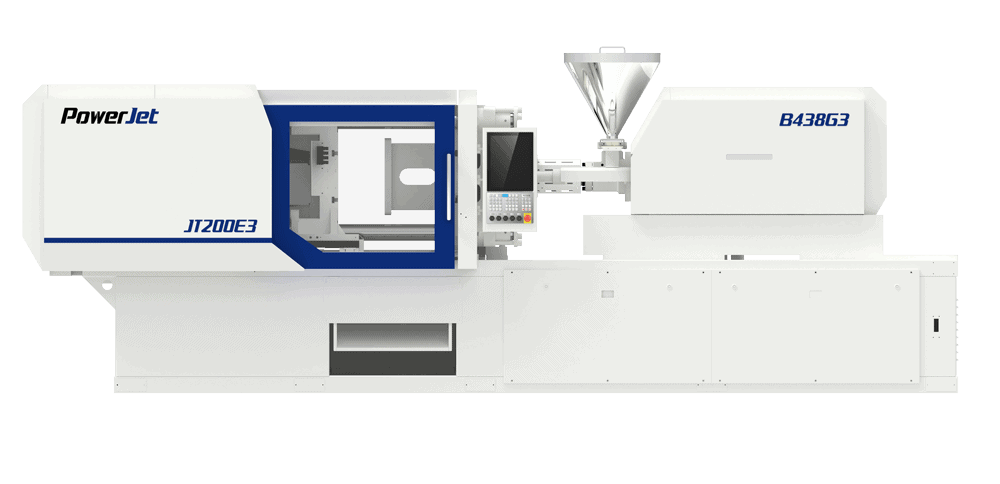

All-Electric термопластавтомат JT Series Smart Manufacturing

From 60 to 450 tons clamping force, meeting the needs of medical, food packaging, and optical products with all-electric injection molding: oil-free cleanliness, precise and repeatable shots, fast thin-wall cycles, and optics-grade surface stability.

What Can Our All-Electric Machines Produce?

From medical-grade precision to optical clarity, our all-electric injection molding machines deliver exceptional quality across diverse industries.

LED Automotive Optical Lens

PMMA indicator lenses molded in an 80-cavity tool at ~55 s per shot. Cooling and hold are tuned for optical parts, so thickness stays even, birefringence is low, and edges are clean for laser trimming.

Material PMMA Power Consumption 8.8 kWhPET Blood Collection Tube

This setup uses an all-electric press and a 48-cavity mold with a ~9-second cycle. It stays stable over long runs; the clean, oil-free process and closed-loop control help maintain uniform wall thickness, roundness, and transparency.

Material PET Dimensions 13*100mmFood-Safe Packaging Molding

All-electric press with a 16-cavity mold runs ~7-second cycles for in-mold-labeled cups. The oil-free, closed-loop process holds wall thickness, rim accuracy, and surface finish steady so labels seat flat, stacks stay even, and sealing stays reliable—suited to instant-coffee packaging.

Material PP Weight 3.3g

Core Component Advantages

The core of all-electric injection molding machines lies in their advanced injection unit and clamping unit design, providing reliable assurance for precision manufacturing.

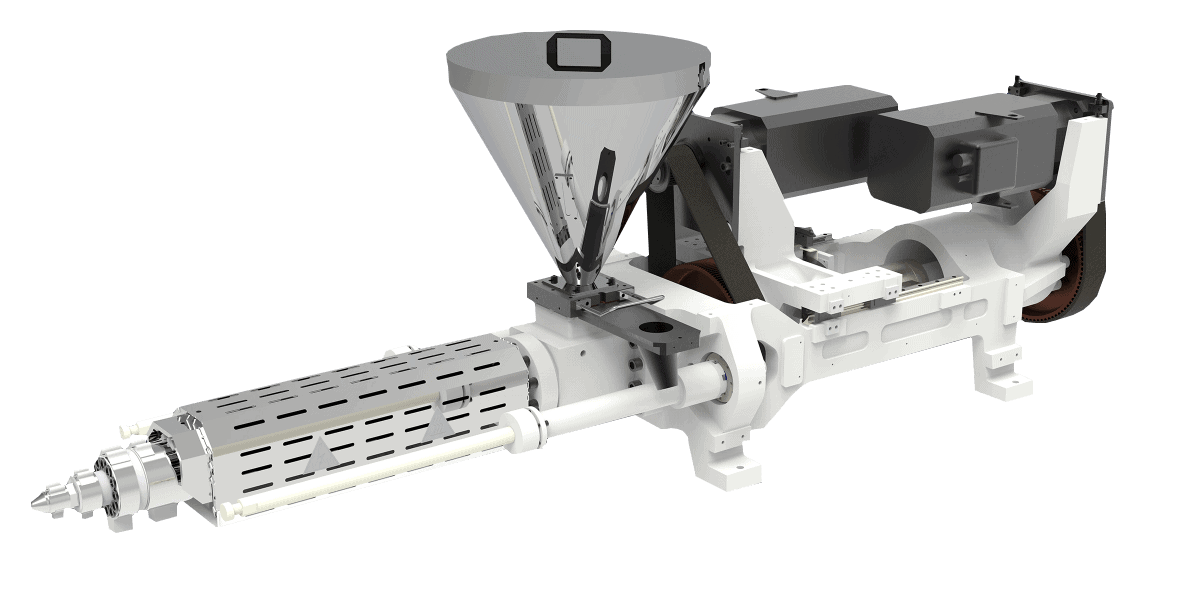

All-Electric Injection Unit

Utilizing high-precision servo motor drive to achieve precise injection speed and pressure control. Supports rapid response and fine-tuning control, ensuring consistency and precision of molded products.

High-Speed Precision Injection

Injection speed up to 300mm/s, response time less than 10ms, achieving fast and efficient production

Intelligent Pressure Control

Multi-stage pressure control, precisely adjusting injection and holding pressure processes, ensuring stable product quality

Energy Saving & Environmental

Over 40% energy savings compared to traditional hydraulic systems, no hydraulic oil pollution, low maintenance costs

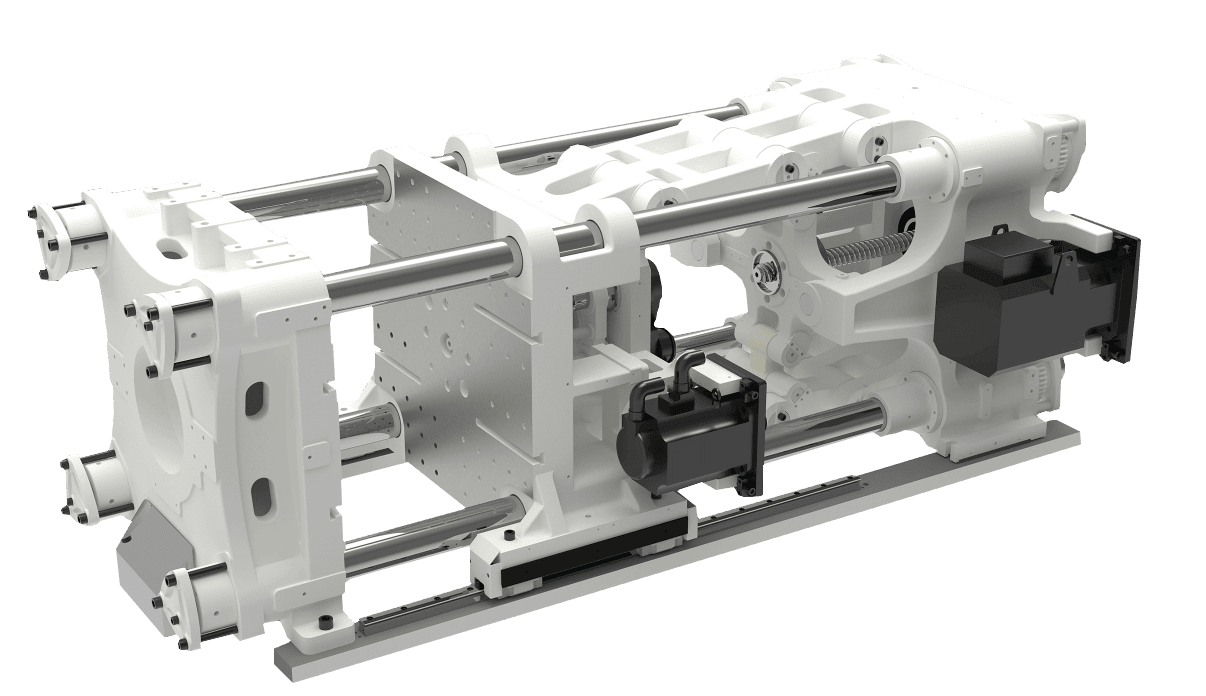

All-Electric Clamping Unit

Precision electric clamping system providing stable and reliable clamping force control. Adopting high-rigidity design and precision guide mechanism, ensuring accurate mold alignment and long-term stable operation.

Optical-Grade Mold Alignment

Mold alignment accuracy ±0.02mm, specifically designed for optical lens precision molding

Multi-Level Safety Control

Medical device-grade safety control with multiple protection mechanisms, ensuring production safety

Cleanroom Compatible Design

Compliant with cleanroom design requirements, oil-free, suitable for food and medical production

Injection Unit Modular Matching

The modular design of Powerjet injection molding machines allows flexible matching between clamping units, injection units, and screw sets.

JT60E

60 150-370mm 80mm 19.6kNJT90E

90 150-410mm 80mm 19.6kNJT120E

120 150-480mm 100mm 29.4kNJT160E

160 180-520mm 120mm 29.4kNJT200E

200 200-550mm 150mm 44.1kNJT248E

248 220-600mm 150mm 49kNJT300E

300 280-650mm 160mm 58.8kNJT360E

360 320-750mm 160mm 58.8kNJT450E

450 350-830mm 200mm 98kNB70

71 200mm/s 300mm/sB120

119 200mm/s 300mm/sB188

195 200mm/s 300mm/sB288

289 200mm/s 300mm/sB438

437 200mm/s 300mm/sB680

686 200mm/s 300mm/sB1000

1028 200mm/s 300mm/sB1320

1322 200mm/s 250mm/sB1800

1778 200mm/sB2250

2239 200mm/sB3000

3033 200mm/sSelect Clamping Unit

Compatible Injection Units

JT Series in Shorts

Quick insights into Powerjet all-electric injection molding machine applications through short videos

All-Electric Injection Molding Machine Precision Molding Demo

#PrecisionManufacturing #InjectionMolding #AllElectric

Watch on YouTubeBlood Tube IMM

#Bloodtube #InjectionMolding #AllElectric

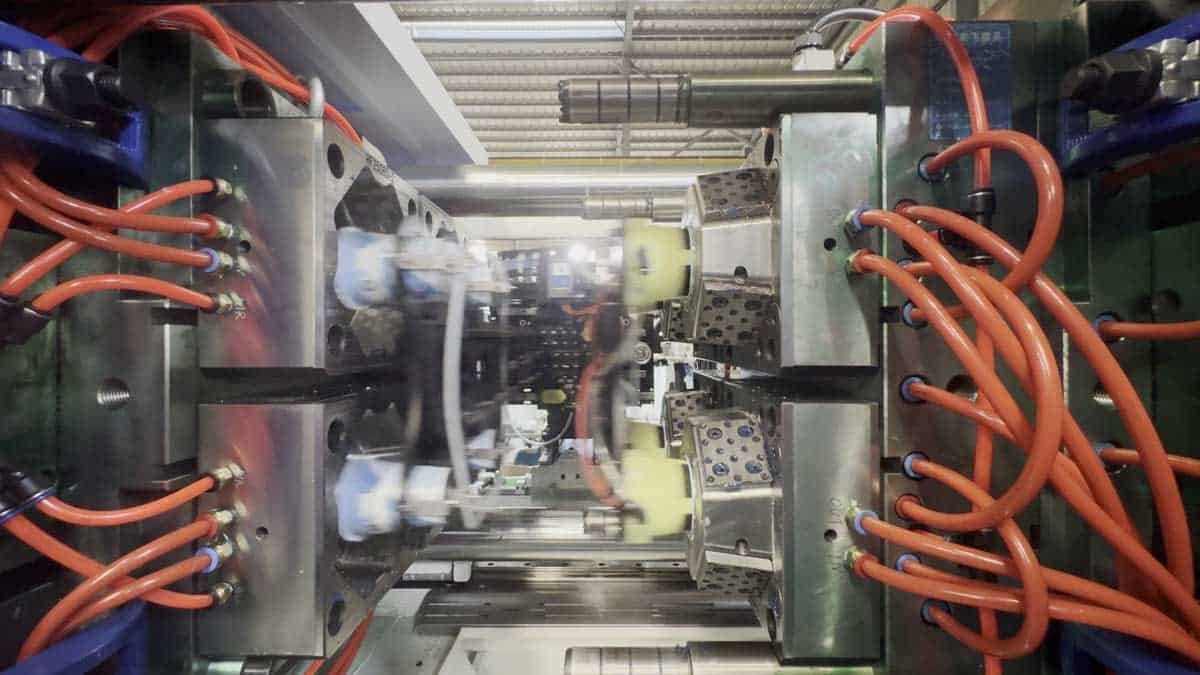

Watch on YouTubeYour Production Excellence Starts Here

Experience the precision and reliability of Powerjet's manufacturing facility. Our all-electric injection molding machines are engineered and tested in state-of-the-art production environments like the one you see here.

From medical-grade cleanliness to optical precision, every machine delivers the performance your industry demands.

Request a Free Quote

Пожалуйста, сообщите нам ваши требования в деталях, мы свяжемся с вами в течение 24 часов.