How to Choose Plastic Bottle Caps Production Equipment?

Oct. 18, 2022

There are two main types of plastic bottle cap production equipment: compression molding machines and injection molding machines, each with its own advantages and disadvantages.

Compression Molding Machines

Advantages:

- High production efficiency

- Better visual appearance by avoiding gate marks

- Easy to maintain molds

Disadvantages:

- Single function, only ordinary caps can be produced

- Finished plastic bottle caps cannot be produced at one time

- Secondary processing may be required after compression molding

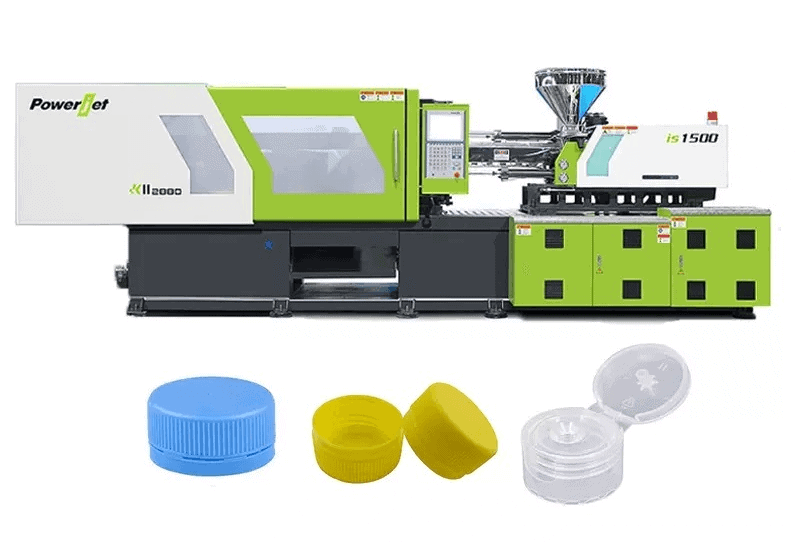

Injection Molding Machine

Advantages:

- Flexible cap style design by purchasing various molds

- Not only can produce ordinary caps, but also some special functional caps: such as flip-top caps, two-color caps, etc.

- Not limited to the production of bottle caps, but also other plastic products such as bottle handles

- High-dimensional precision

Disadvantages:

- The production efficiency is lower than that of the compression molding machine

- The cost of replacing and maintaining the mold is high.

How to choose plastic bottle caps production equipment?

Should you choose injection molding machines or compression molding machines?

In general, injection molding machine has advantages over compression molding machines if you are not just producing regular plastic bottle caps.