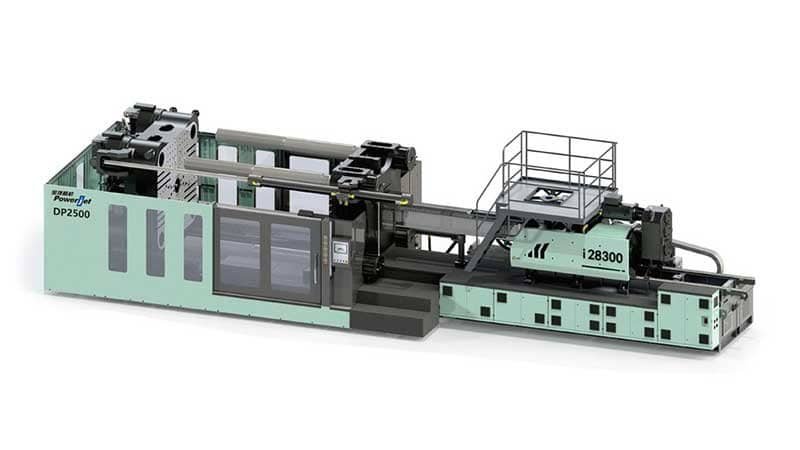

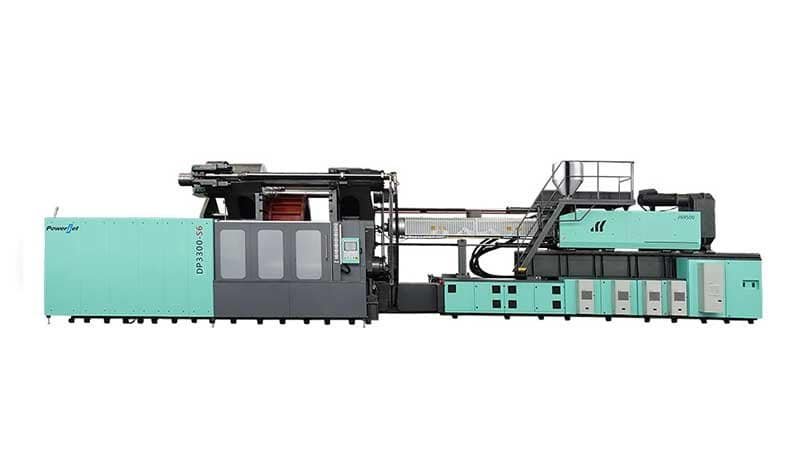

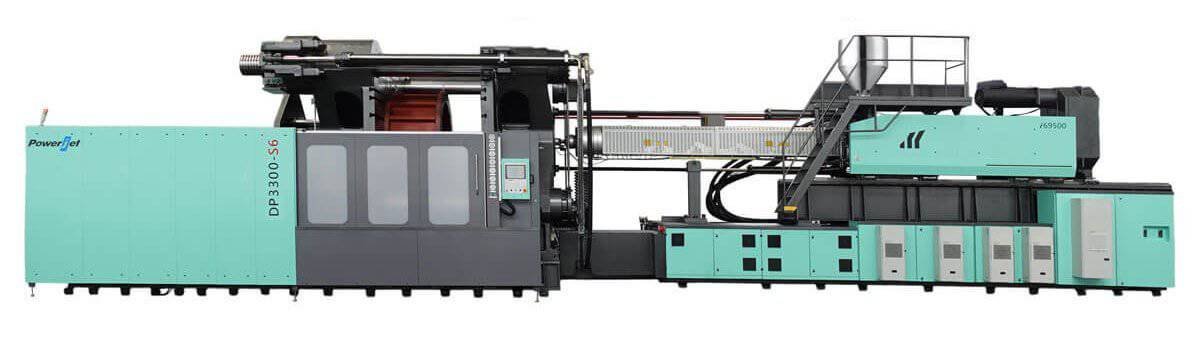

Powerjet Two Platen

Injection Molding Machine

A Long-term Investment in Reliability

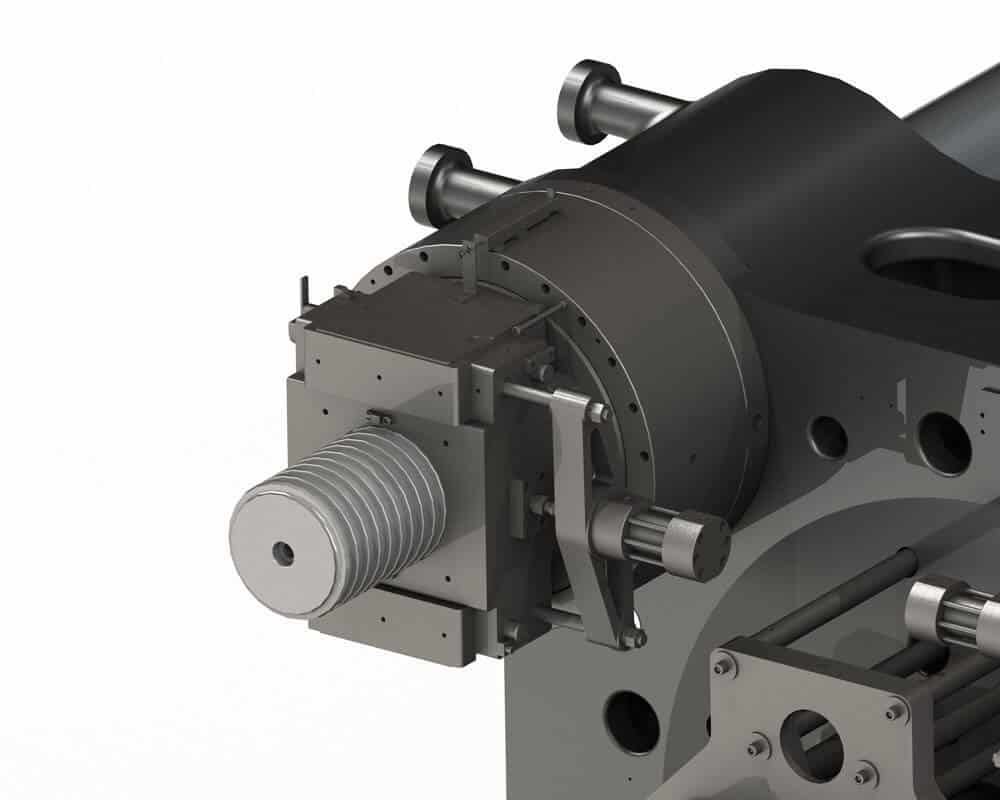

Our Two Platen Injection Molding Machines with innovative Fixed Tie-bar system

and independent oil cylinders enhance durability and offer a distinct advantage in lowering maintenance costs.

Choose Powerjet for a dependable, long-term solution to your manufacturing needs.