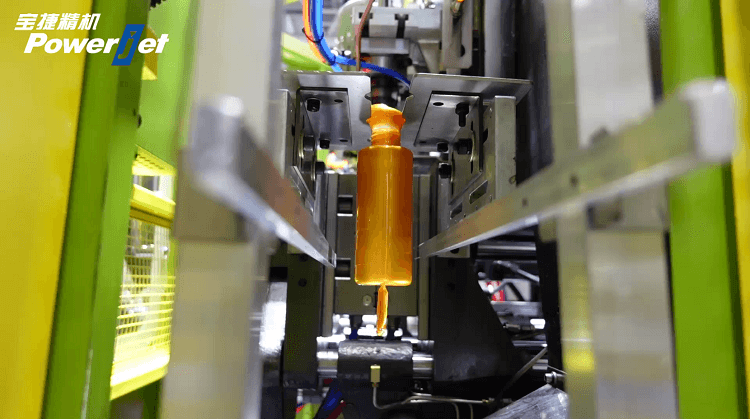

Powerjet EB10H Extrusion Blow Molding Machine K 2022 Exhibition Model

Sep. 28, 2022

Powerjet automatic extrusion blow molding machines have lower total power and lower energy consumption than the same screw models.

In addition, the center of gravity of the machine is relatively low, and the speed reduction valve brake is used to move the mold so that the machine can move relatively quickly and smoothly, and the productivity per hour is higher.

In comprehensive comparison, Powerjet blowing equipment has obvious advantages in income and performance.

Features of the machine

- Highly efficient and stable: short molding cycle, high output, central oil cylinder structure of locking template, strong and uniform clamping force, special mold shifting reduction valve, fast and accurate positioning, no impact;

- Intelligent: professionally designed blow molding machine control system and PLC, modular design, flexible expansion and change, central monitoring, network remote diagnosis, intelligent centralized temperature control, automatic alarm and fault feedback, highly user-friendly parameter settings, easy to master, easy to operate;

- Fast color change: unique screw parameter design, combined with precise temperature and speed control, plasticization and mixing to achieve the best results, uniform and bright color, deep mirror treatment inside the die, smooth curved flow path, no dead ends, No carbon deposit, uniform and dense extruded rubber embryo thickness, fast color change.

Application

Mainly produce PETG thick-bottom bottles, double-layer high-gloss bottles, and high-end cosmetic bottles for color cosmetics.

Powerjet Plasticizing The Beautiful World, Always For You!

Join us and learn more about how we can solve your injection molding and extrusion blow molding problem.

See you in Düsseldorf, 19-26 October!

Come and meet us at Booth D39 in Hall 13.

Powerjet Cosmetic Bottle Packaging Hollow Molding Solution

Applied Range:| Product | 10-1000mL Cosmetic Bottles |

|---|---|

| Mold Cavity | 2 Cavities |

| Weight | 3-50g |

| Material | Double-layer PETG |