How to Start up an LED Bulb Injection Molding Production Line?

Nov. 21, 2022

You and your clients may be aware of the potential market for LED Lighting business locally or abroad. When it comes to choosing the injection molding machines, questions will come to your mind…

Which parts should injection molding machines for production?

What material to choose?

What injection molding machines does Powerjet offer?

Which Parts Need Injection Molding Machines for Production?

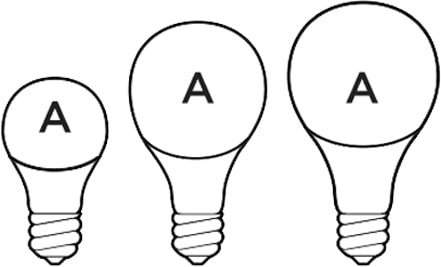

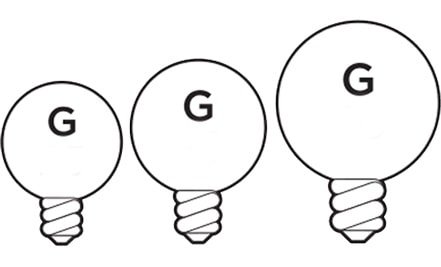

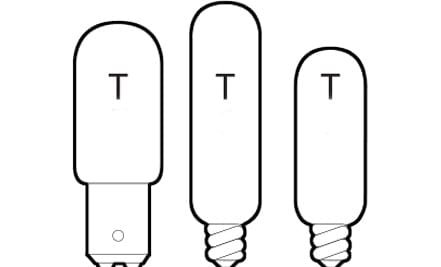

Checking the most popular type of LED bulbs, A-type, G-type, and T-type are suitable for production with an injection molding machine. Their main structures which could lower costs in long-term business with injection molding machines are the lamp covers and plastic housing.

Then we need to know the dimension of the bulb, the most common ones are produced in 60mm and 65mm diameter, which mean A60 and A65 Led Bulb. The weight is important as well. For example, the A60 covers a weight of around 6.5g. The lighter the weight of the same type of light bulb, the more difficult it is to make the molds.

Last but not least, how many LED bulbs do we want to produce per hour? Then the injection molding machine manufacturer – Powerjet Plastic Machinery can choose the right tonnage of the machine and make sure the mould can meet the requirement.

Aim for best selling for the LED lighting product, quality and cost control of each part is important to manufacturers. Color shade steady, evenly, smooth, and high transmittance for PC LED light bulb cover; the housing part should be high heat conductive and heat-resistant PBT material. While some manufacturers may need to use modified plastic kind, your golden samples of each part need to send to us for reference.

About PowerJet IBM-R series Rotary Injection Blow Molding Machines:

- Easy for operation and maintenance.

- The rotary part is controlled by servo motor, which ensures the rotary accuracy.

- Reasonable and scientific mold structure to reduce the production inputs.

- The appearance quality is perfect without parting line.

- Suitable for the industry which is strict for the product appearance (LED bulb PC Cover,etc.)

Compare with standard injection molding machine with preforming at 1st step and then blowing, POWERJET IBM-R Series could one-step finish(preforming and blowing at the same time). Shorten production time and enhance production capacity.

Powerjet also provides KII series high precision injection molding machines to produce LED lamp PBT housings!

LED Bulb Cover Injection Molding Production

Case for Reference:| Machine Model | IBM288R-S6 |

|---|---|

| Product | LED Cover A60 |

| Mold Cavity | 16 Cavities |

| Weight | 6.5g |

| Cycle Time | 19s |

| Material | PC |